Evonik catalyst supplies oxygen to astronauts on board the ISS

A catalyst developed by Evonik and Airbus for the International Space Station (ISS) will be helping provide breathable air for manned space missions. ISS Commander Alexander Gerst installed the system.

Designed to help produce oxygen on board spacecraft, a life-support system made by Airbus for the European Space Agency (ESA) revolves around a Sabatier reactor with an Evonik catalyst. German astronaut and ISS Commander Alexander Gerst has now installed the module, which will begin operation in early 2019. The system is to undergo testing through the end of the year to assess its serviceability.

The ACLS (advanced closed-loop system) is a life-support system that produces oxygen, water, and, as a by-product, methane. The heart of the system is a fixed bed catalyst from Evonik installed in what is known as a Sabatier reactor.

Ten times the CO2

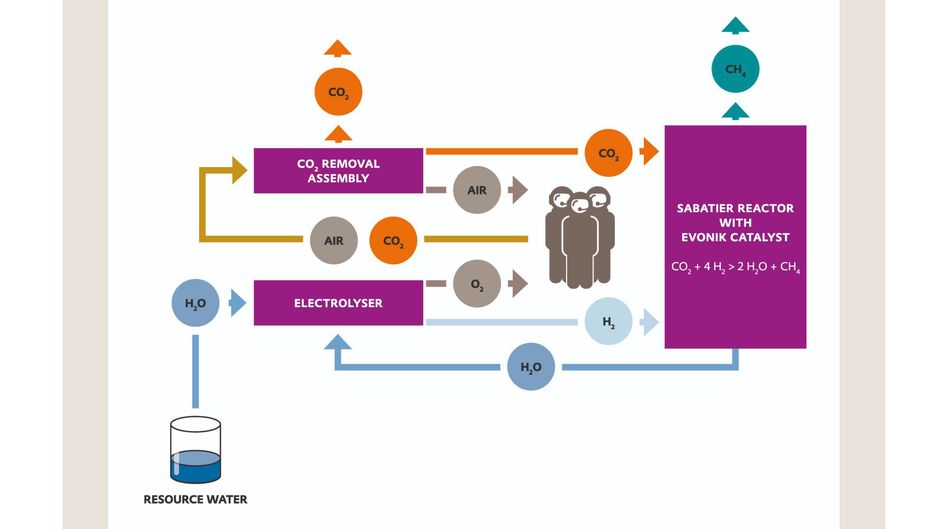

At 0.4 percent, the concentration of carbon dioxide in the air inside the ISS is ten times higher than that on earth—the ACLS is expected to change that. Before air is circulated back into the space station, carbon dioxide is first separated out. Inside the Sabatier reactor, this CO2 passes over the catalyst, where it reacts with hydrogen (H2) that has been fed into the system to form water (H2O) and methane (CH4). The reaction proceeds in two steps, with temperatures reaching some 550 degrees Celsius during the first step and 200 degrees during the second.

But where does the hydrogen come from? The ACLS produces that too. Solar power generated by the ISS is used for driving an electrolysis reaction that splits water into oxygen and hydrogen. The resulting pure oxygen is mixed into the breathable air, while the hydrogen is used for the Sabatier reaction. The advantage here is that, because H2O is produced in the Sabatier reactor, the system can supply itself with up to 40 percent of the water it needs. And transporting water to the ISS is extremely complicated and expensive—up to €60,000 per liter, which adds up to millions of euros in savings.

A solution for Mars missions too

While currently designed for a crew of three, the ACLS also offers a solution to the problem of supplying oxygen to space travelers on longer missions—say to Mars—in a way that is both effective and conserves resources.

Development of ACLS was conducted in the aerospace division of Airbus. Evonik’s Catalysts Business Line has been cooperating with Airbus on this for nearly 20 years, focusing on the Sabatier catalyst. Following successful tests on Earth, the system is now operable for the first time on the ISS. The ACLS, which will be controlled by Airbus employees in Friedrichshafen in cooperation with the ESA and NASA, was transported from Earth in the Japanese HTV-7 space transfer vehicle. The HTV-7 is currently the only spacecraft with a cargo hold large enough for the apparatus.