HPPO plant

TS1 Catalyst

Hydrogen Peroxide to Propylene Oxide Technology of Evonik and thyssenkrupp

The HPPO process is an innovation success story: this clean technology for the production of propylene oxide (PO) from propylene and hydrogen peroxide (H2O2) was jointly developed with thyssenkrupp – and involves a special catalyst from Evonik.

In the HPPO process hydrogen peroxide (H2O2) is used as the oxidizing agent to oxidize propylene to propylene oxide (PO). Evonik’s customers use propylene oxide to produce polyurethane precursors and intermediates. Polyurethane foam is used to insulate refrigerators and houses, make cars lighter and more economical, and enhance the comfort of mattresses and upholstered furniture.

In the plant engineering experts from thyssenkrupp (formerly Uhde), Evonik found an exclusive strategic partner to complement its extensive catalyst and hydrogen peroxide know-how.

Combining their specific strengths resulted in a one of a kind solution for the production of propylene oxide. thyssenkrupp is the contracting and engineering partner for the hydrogen peroxide plant and the propylene oxide plant and Evonik supplies the catalyst and H2O2 “over the fence”.

The catalyst – Ever more effective

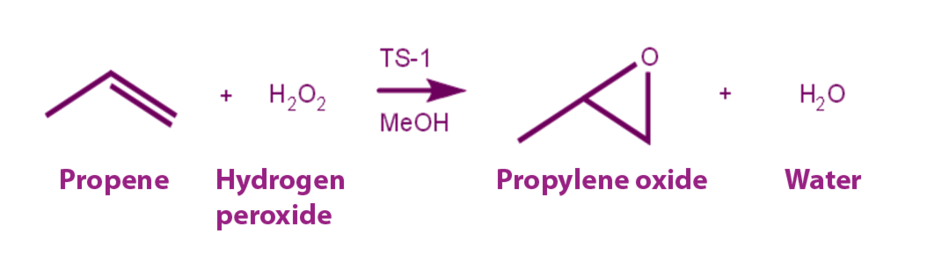

Propene and hydrogen peroxide would not react without high energy expenditure, they must first be activated. The by-product-free HPPO process utilizes a catalyst system based on a specifically developed and tailored titanium silicalite-1 (TS-1) from Evonik, sold under the Specialyst® brand.

With this catalyst, Evonik has designed a heavy duty performer delivering selectivity rates exceeding 95 percent. The excellent incorporation of titanium into the zeolite structure with its optimized pore size guarantees a high activity and selectivity as well as a long service life. The inorganic mixed oxide, with a structure in the nanometer range, is synthesized in the form of a powder and then formed into extrudates.

Both the catalyst itself and its production are subject to constant innovation efforts. Recently, a new generation of the catalyst was launched that shows improved performance and service life.

Putting the HP in HPPO

To date, hydrogen peroxide (HP) has been used mainly as a bleaching agent by the textile and paper and pulp industry. The HPPO process allows this eco-friendly oxidant to be employed in the direct chemical synthesis of propylene oxide. As a leading manufacturer of H2O2, Evonik has extensive experience with both the product and the new process. Moreover, Evonik offers a grade of H2O2 specifically designed for the epoxidation of propene, which makes Evonik the preferred hydrogen peroxide supplier for this application.

What are the benefits of the HPPO technology?

Used as an oxidizing agent to oxidize propylene to propylene oxide (PO), hydrogen peroxide only produces water as a by-product. This process is significantly more environmentally friendly than other competing technologies.

Formula propene to propylene oxide

Operation of the Evonik-Uhde HPPO process is extremely cost-effective due to the efficient feedstock consumption, a high-performance catalyst and low capital investment. The epoxidation reactor is specially designed for the exothermic reaction resulting in optimal selectivity.

Compared to other state-of-the-art PO technologies, the Evonik-Uhde HPPO process also entails lower capital investment, thus allowing investors to be more flexible in their investment decisions. With its sustainable production concept the HPPO technology is superior to other propylene oxide production processes.

Successful commercial operation

Since 2008, the Evonik-Uhde HPPO technology has been in successful commercial operation at the world's first plant based on this process, owned by SKC of Korea. The second of its kind is a world-scale HPPO operation with 300,000 metric tons of propylene oxide owned by Jishen Chemical Industry Co. Ltd located in China and has been operating since 2014. . A third plant with 200,000 metric tons of propylene oxid is under construction at MOL in Hungary, which will start-up in 2021.

HPPO Technology Benefits

- Lower investment costs compared to alternate technologies

- Efficient raw material consumption

- Co-product free and environmentally friendly

- Specifically designed proprietary catalyst with high yield, activity and selectivity

- Continuous process optimization

- Outstanding process technology support

- Evonik’s advanced technology know-how and operation experience