Catalyst Regeneration Services

Moving Belt Technology and optiCat Plus®

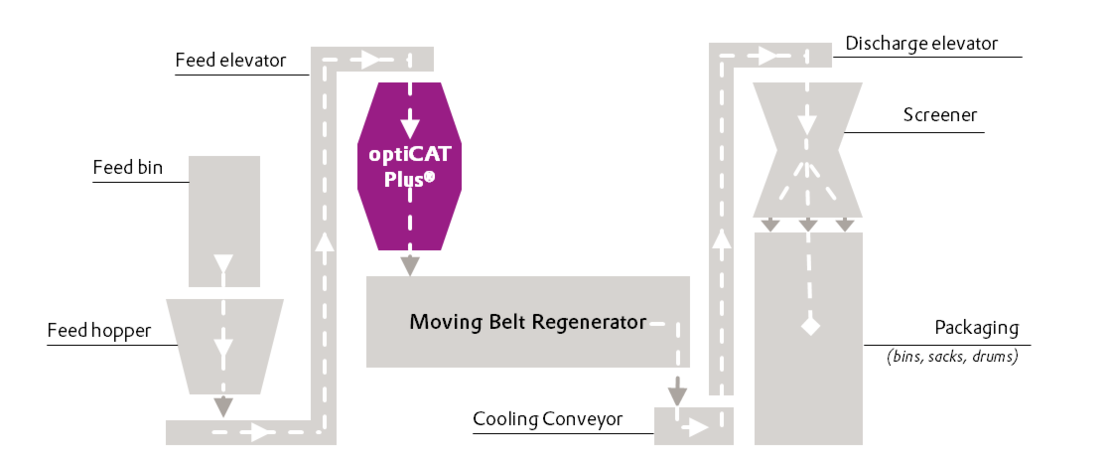

Evonik’s advanced moving belt technology combined with our optiCAT Plus® stripping unit reduces costs, improves yields, and restores spent catalyst to its maximum potential.

Why it works

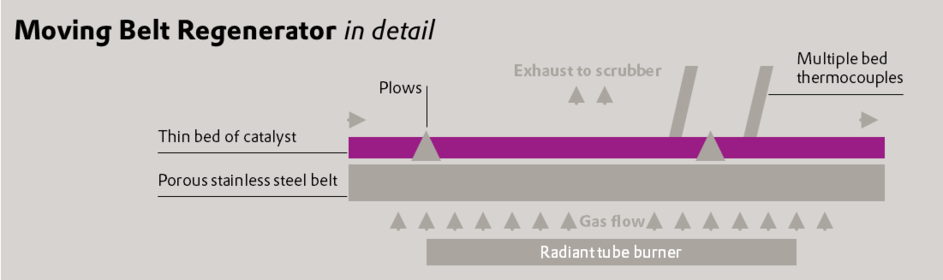

The sophisticated control system of the moving belt process minimizes problems with channeling, hot spots and sintering. A thin bed of material is transported through multiple regeneration zones on a porous, stainless steel belt.

Radiant tube burners heat the air and combustion gasses flowing through the catalyst bed. Multiple thermocouples in each zone monitor the bed temperatures as the carbon and sulfur impurities are removed by controlled oxidation.

Recent improvements in our regeneration temperature control system virtually eliminate the risk of thermal damage to the catalyst and allow us to regenerate of catalysts to their maximum possible activity.

Through excellent temperature control, we avoid pore collapse, which prevents surface area reduction and sintering. Multiple plows along the regeneration belts gently turn over the catalyst to ensure it is regenerated evenly. This minimizes breakage and attrition, which is particularly important when regenerating eggshell-type precious metal catalysts. The improved stripping efficiency resulting from optiCAT Plus®, reduces the dwell time on the belt regenerator, which increases throughput and product quality and results in a milder catalyst regeneration.

By combining optiCAT Plus® with the moving belt process, we restore catalysts and adsorbents to their maximum potential with minimal breakage.