Evonik Catalysts

Innovative technologies

Most chemical processes use catalysts in granule, extrudate, tablet or powder form. At Evonik, we are constantly asking ourselves how to make a difference. That’s why we have developed a much better alternative to conventional catalysts for fixed-bed applications. Our innovative metal foams are a game changer. They perform better, are more efficient and sustainable.

Our nickel foam catalysts make hydrogenation reactions easier, more profitable and safer. This is because their low weight combined with a very large reactive surface area enables them to deliver the same product performance in a smaller quantity.

See how we make a real difference with our innovative nickel foams.

Catalysts are the key component in chemical processes, determining the practicability and applicability on large scale. For continuous hydrogenation, companies are still using the same traditional catalyst types which were developed decades ago. But with today’s innovation there are better ways.

With our solutions we make hydrogenation reactions easier,

safer, sustainable, and more profitable.

Let's make a difference.

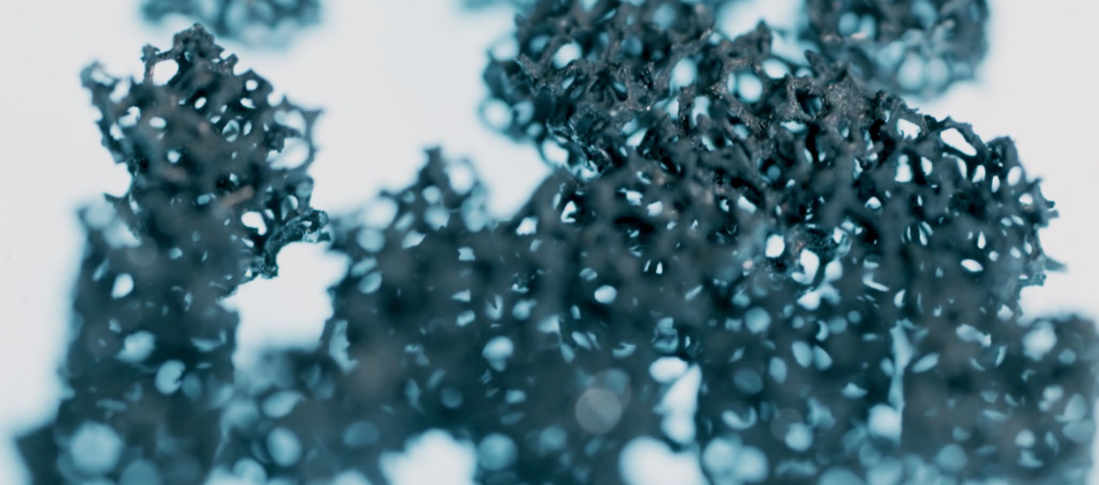

Little metal, large surface: Ultra-efficient nickel foam

Our nickel foams are lightweight with a very large reactive surface. On a volume basis, our nickel foam catalyst bed contains only a very small fraction of metal. However, this metal is used in a very efficient manner. Thanks to a vast reactive surface, considerably less quantities of catalyst are needed to maintain the same product output.

Even at two millimeters thickness, our catalyst’s structure allows light to pass through. And since liquids can flow through the nickel foam, the pressure drop is extremely low and the catalyst bed hardly rises and falls – resulting in less abrasion. This pays off in longer catalyst life and reduced maintenance costs in downstream equipment.

With our nickel foam, the catalyst bed hardly rises and falls.

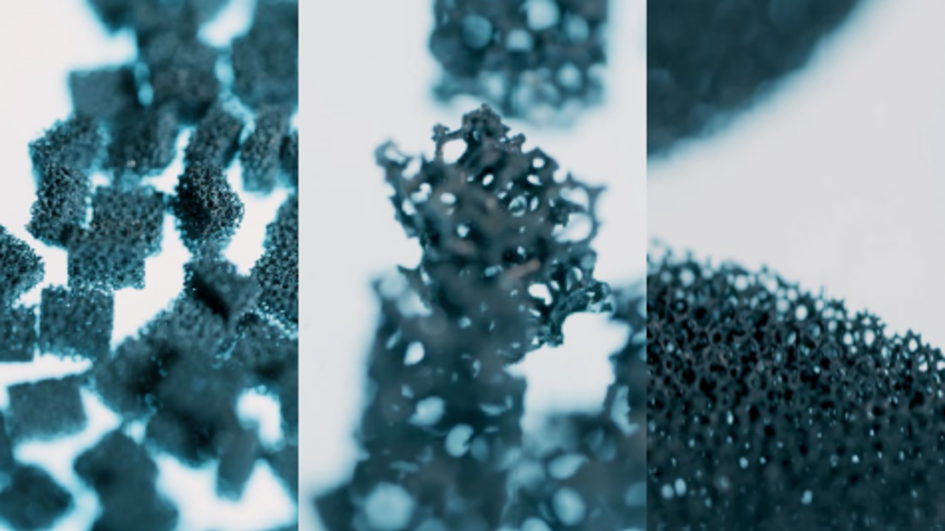

Tailored to your needs: Customizable shapes and pore sizes

By default, we cut the two-millimeter-thick nickel foam plate into platelets of 4 x 4 millimeters. But your needs may vary – we can adjust shapes and pore sizes to your use cases.

Square platelets or tiny discs – we fulfill your every catalyst wish.

Before shipping the foam catalysts in water-filled drums, we activate them by leaching the surface to generate a ready-to-use product. Our activated foam catalysts can be poured directly from the drum into the reactor without hazardous dust or elaborate protective measures. This makes your catalyst exchange much faster and safer.

Shipped in water, the catalysts can be used straight from delivery.

|

WHAT'S IN IT FOR YOU? |

|

|

|

Dr. Christoph Kins

Christoph holds a PhD in Chemistry. He has been working with Lanxess in Polymer Research before he joined Evonik in 2015 as Sales Manager EMEA. Since 2020 he is globally responsible for the Product Group Activated Metal Catalysts.

Foam catalysts are manufactured under a license from Alantum Europe GmbH