Manufacturing partially saturated free fatty acids with Evonik Catalysts

Partially saturated free fatty acids (FFA) impart a different functionality to oleochemical products compared to fully saturated FFA. They are produced under conditions with catalysts that favor the formation of monoenes (fatty acid chains with only one double bond) and more than likely, trans fatty acids (TFA) as well. This technology has been historically developed for triglycerides and recent developments have also been used for advancing the partial hydrogenation of FFA.

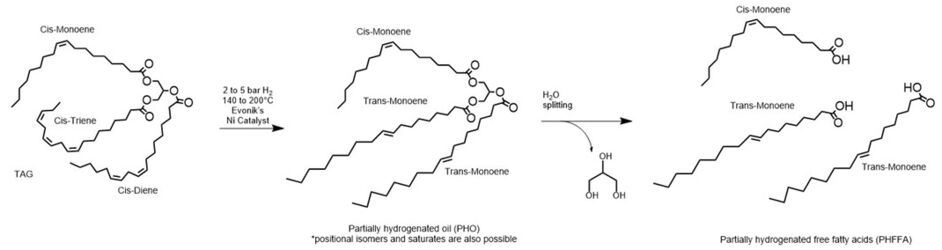

The partial hydrogenation of triglyceride feedstocks followed by splitting to obtain partially hydrogenated FFA

Figure 1 displays the reaction route for the partial hydrogenation of triglycerides followed by splitting to create partially hydrogenated FFA. Table 1 shows the influences of increasing the H2 pressure, temperature and catalyst dosage on the amount of surface nickel hydrogen, the reaction rate, the solid fats content (SFC) curve and the selectivity values of saturates, monoenes and TFA1, 2, 3, 4, 5 . Anything that forces the reaction deeper into hydrogen mass transfer control will increase the amount of monoenes and TFA leading to a steeper SFC curve. The lower hydrogenation pressure of triglyceride hydrogenation favors higher monoene and TFA contents, thereby making the route of hydrogenation followed by splitting a preferred method for producing partially hydrogenated FFA. Sulfided nickel catalysts1, 2, 4 can be used alone or in combination with standard triglyceride nickel hydrogenation catalysts to improve the above-mentioned selectivity for higher monoene and TFA contents. Evonik’s sulfided nickel catalyst for this application is MONCAT® 4181.

The effect of triglyceride hydrogenation conditions

|

|

Influence of H2 conc. on Ni surface |

Influence on reaction rate |

Influence on saturate selectivity |

Influence on monoene selectivity |

Influence on TFA selectivity |

Influence on solid fats content curve |

|

H2 pressure |

increase |

increase |

increase |

decrease |

decrease |

flatter |

|

Temperature |

decrease |

increase* |

decrease |

increase |

increase |

steeper |

|

Catalyst dosage |

decrease |

increase* |

decrease |

increase |

increase |

steeper |

*Until the reaction becomes totally mass transfer controlled

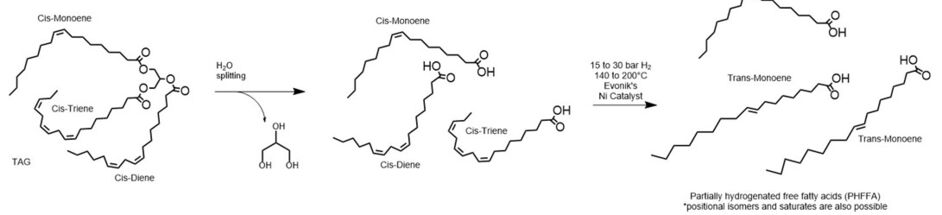

The partial hydrogenation of FFA feedstocks to obtain partially hydrogenated FFA

Partially hydrogenated FFA can also be manufactured by first splitting triglycerides followed by moderately hydrogenating the FFA as seen in Figure 2. The monoene and TFA selectivities can be improved by adjusting the temperature and catalyst dosage as described above for triglycerides. However, the hydrogen pressure should be kept high to prevent nickel soap formation. Specially designed sulfided nickel catalysts can be used either alone or in combination with standard FFA hydrogenation catalysts to improve the monoene and TFA selectivity further. Evonik’s sulfided nickel catalyst for this application is MONCATTM 5191.

Sources:

1 R. D. O’Brien, “Fats and Oils: formulating and processing for applications”, 3rd ed., CRC Press, Taylor & Francis Group (2009).

2 H.B.W. Patterson, “Hydrogenation of Fats and Oils: Theory and Practice”, AOCS Press (2009).

3 M. K. Gupta, “Practical Guide to Vegetable Oil Processing”, 2nd ed., AOCS Press, Elsevier (2017).

4 W. E. Farr, “Hydrogenation: Processing Technologies” in Bailey’s Industrial Oil and Fats Products, 6th ed., John Wiley & Sons, Inc. (2005).

5 M. Bockisch, “Fats and Oils Handbook”, AOCS press (1998).